ig-metal-cutting-gas

Metal Cutting Gas (MCG)

A 100 lbs./44 KG. Cylinder of Metal Cutting Gas provides over 5 times the BTUs of a standard 5 m3 or 5 cubic meter Acetylene cylinder, while costing less. Here is what it means to you.

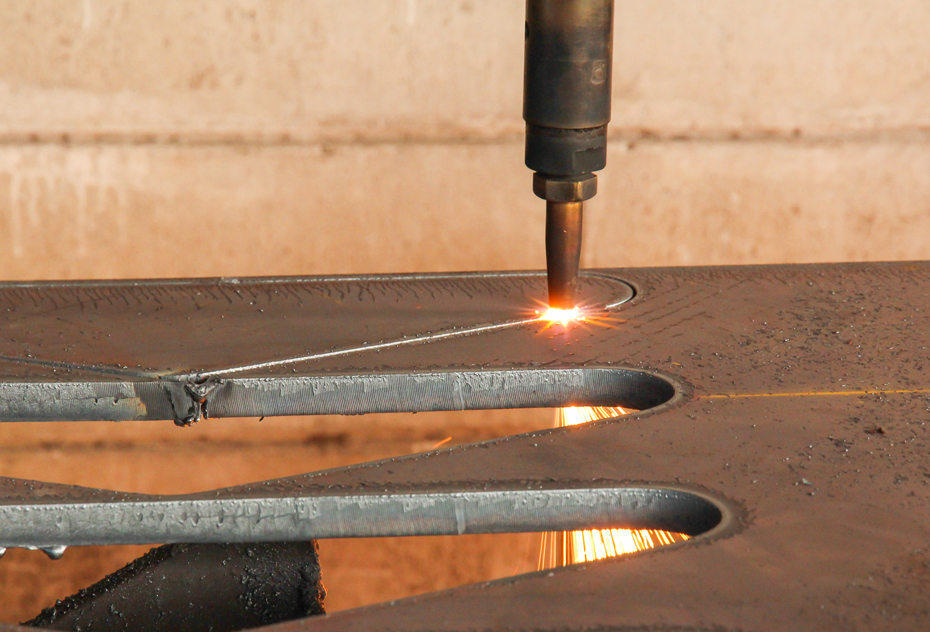

Finally there is a reliable fuel gas for cutting, heating, and brazing operations that will provide higher performance than acetylene, at a much lower price. MCG is the new standard of economy, performance, and safety for gases used in these metalworking processes. MCG is a superior high temperature, high heat content fuel gas.

Faster preheat and piercing rates for cutting.

The piercing flame temperature of MCG Fuel Gas exceeds the flame temperature of most cutting fuels. It starts the cut as rapidly as acetylene and preheats and pierces faster than other combined cutting fuels at a lower cost

Faster cutting travel speeds.

MCG Fuel Gas is capable of cutting travel speeds equal to acetylene while using lower quantities of oxygen than acetylene during cuts of up to 15″ thick. if Normal LPG or any other cutting fuels are used, they are much slower and also require much more quantities of O2 for the same amount of production.

The highest combined inner and outer flame temperature plus the neutral flame temperature in oxygen provides the highest total heating value in the industry. MCG Fuel Gas has greater practical value than any other cutting fuel.

Reduces slag formation and easier removal.

MCG Fuel Gas contains a balanced compound of metal organic material in a pure hydrocarbon solvent. The combustion catalyst of metal organic compounds inhibits the formation of molten slag, changing it into a material which is vaporized in the burning process and deposited in dry form. The result is the smoothest surface after cutting.

Faster heat transfer for brazing, heating, ending, cambering, straightening, hardening, and melting operations.

Whether you are using an MCG and Oxygen mixture or an MCG and air mixture, the superior heating value (neutral flame temperature and inner and outer flame temperature), that is the total heating value, allows for faster heat transfer to the metal. This means faster brazing, heating and metal working operations.

Safer and operator friendly.

Non-toxic, non-injurious to health. No torch backfire. Non-sensitive to shock with a low explosive range. Creates no dangerous by-products. No annoying fumes and easy to use with standard equipment for LPG fuel gases. Long life for two-piece, non-fouling recessed tip torches used for cutting.

Supply Options

Products can be supplied in Cylinder, Toners or various other forms as per needs of the

customers. Tailor-made solutions in supply chains ensure reliability and continuous gas

supply.